1) Can you give information about the technical features of Kiasma’s dredger pipelines? What kind of pipelines you manufacture?

Kiasma - Italian EPS (Engineering Procurement Services) in line with IPCC and COP21, since 2018 is constantly committed to make its contribution to Social, Environmental and Economic Sustainability. We have developed, produced and patented KNN33_4.0® Thermoplastic TP-E "Eco-Hybrid Samrt Machine" discharge lines which, by using Energy produced from Renewable Sources, are able to reduce CO2 Emissions in the Atmosphere and Microparticle Emissions in the Marine Ecosystem and through the KRC® (Kiasma Remote Control) System, unique worldwide, we are able to control and monitor via wireless the parameters of: Thickness - Pressure - Temperature - Weight & m3.

2) What are the most appreciated qualities of Kiasma’s pipelines by their users?

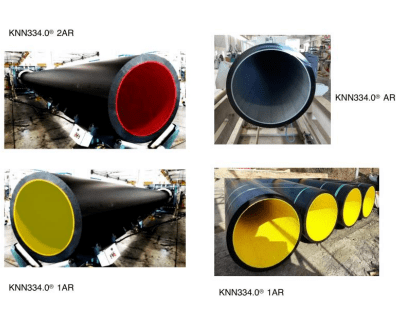

KNN33_4.0® AR -1AR -2AR Mulilayer Thermoplastic TP-E System, thanks to its physical and mechanical properties offers performance in terms of: high Abrasion resistance, Strength and Resilience.

With a lifetime 3 to 5 times longer than traditional HDPE or steel pipes, it significantly reduces the unproductivity linked to machine downtime, also reducing the cost of transport, maintenance costs both on the land and with regard to the rotation of the floating lines.

Thanks to the reduction in abrasion, there is a consequent reduction in the dispersion of Microparticles in the Marine Ecosystem

Associating the KNN33_4.0® System with the KFC © System, which generates a rotational flow, thus bringing the Sediments to a rotational motion condition in the center of the pipeline, the pressure drop is reduced and consequently there is less fuel consumption and less CO2 emissions into the Atmosphere

KRC® Kiasma Remote Control System, Hybrid pipeline device "Eco-Smart Machine" for energy efficiency and additive control of dredging power according to the Sediment behavior in the discharge line. Real-time wireless monitoring of the main parameters along the pipeline: Thickness - Pressure - Temperature - Weight & m3.

KSRC- Kiasma Sediment Remote Control System: dynamics and quantification of sediments in Waterways to anticipate sediment impacts on Environments and Ecosystems in Dams, Lagoons, Ports and Delta.

HARUN GURAN-GURAN MACHINE SALES MANAGER

KIASMA DISPLAYS ITS DIFFERENCE WITH ITS SUSTAINABLE SYSTEMS

3)How does Kiasma’s pipelines differ from its equivalents?

Kiasma, leader in the dredging sector, thanks to its experience consolidated by years of direct activity and presence in the field, thanks to its own Research and Development department and thanks to multidisciplinary scientific collaborations at a high international level, has developed systems that are unique in the world.

Starting from predictive climatological analysis, with consequent study and quantitative modelling of environmental dynamics in transitional systems such as deltas, waterways, lagoons, ports, etc., we have developed an integrated approach for the industrialization of products and technologies capable of reducing CO2 emissions and microparticles in the marine ecosystem, for environmental dredging. With reference to the geology and morphology of the project area, we develop the best technology applied to the dredging discharge lines.